Low Sulfur High Carbon Silicon for Steelmaking as Alloying Agent

Basic Info.

| Model NO. | 55% 60% 65% 68% |

| Model Number | 6015 6515 6818 |

| Color | Silver Gray |

| Transport Package | Ton Bag |

| Specification | 10-150mm |

| Trademark | FEIYUE |

| Origin | China |

| HS Code | 2621900009 |

| Production Capacity | 3000 T/Month |

Product Description

Low Sulfur High Carbon Silicon for Steelmaking as Alloying Agen

Silicon Carbon Alloy

Product Description

As the new alloy for converter, Silicon Carbon Alloy can replace Ferro Silicon to be used as deoxidizer. lower steelmaking cost, increase economic benefit, improve product quality and stable performance.

| Si45 | C15 | 10mm-50mm |

| Si50 | C15 | 10mm-50mm |

| Si55 | C15 | 10mm-50mm |

| Si60 | C15 | 10mm-50mm |

| S65 | C18 | 10mm-50mm |

| Si68 | C18 | 10mm-50mm |

| Other chemical composition and size can be supplied upon request. | ||

High Carbon Silicon-Replacement for FeSi as deoxidizer used in carbon structural steel carbon steel,alloy steel,deformed steel bar manufacturing. High Carbon Silicon 's other name is Silicon Carbon Alloy

Application

1)lt is a good substitute for ferro silicon in steel making which has advantage in reducing the making cost.2)lt is used as multi deoxidizer by silicon&carbon.3)High recovery rate of Si by carbon.4)Less impurity because of high content of Si&C(the content of Si&C around 90%).5)More efficient heating agent:Caloric value of Si&C:6.58kcal/g,1.24kcal/g each.

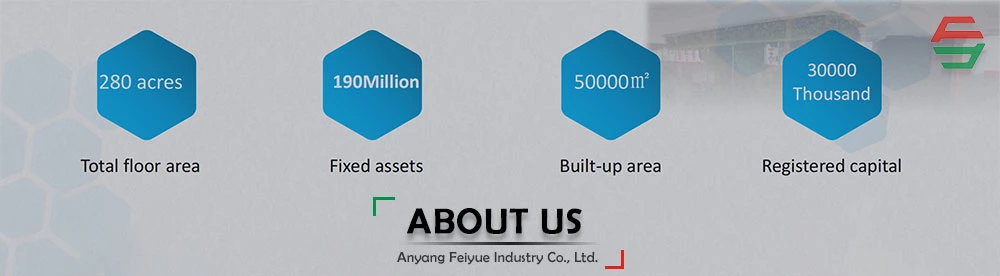

Company Profile

Our main products are ferromanganese, metallic silicon, silicon carbon alloy, cored wire, ferrochrome, silicon manganese alloy, silicon carbide, ferrosilicon, silicon aluminum barium calcium, silicon barium calcium, etc. The company is also engaged in the export business of refractory materials and other metallurgical products. Products can be processed according to customer needs. The company has one 206 cubic meter blast furnace, two 12500 kVA submerged arc furnaces, two 3600 kVA refining furnaces, four medium frequency electric furnaces and three production lines of cladding line, achieving the operation process of manganese series hot charging and hot mixing system and realizing the one-stop production process of high quality, high yield and low consumption.

Q: Are you a factory or a trading company?

We are factories and trading company.

Q: Do you have quality control?

A: Yes, we have gained BV, SGS authentication.

Q:.What is your terms of delivery?

We accept FOB, CFR, CIF, etc. You can choose the most convenient way for you.

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is 25-45 days if the goods are not in stock, it is according to quantity.

Q:Can we get the some samples?Any charges?

A: Yes , we could offer the sample for free charge but do not pay the cost of freight .

Q: What is your terms of payment ?

A: 30% T/T deposit , 70% balance by T/T or L/C before shippment.

Q:Why did lots of customers choose us?

An: Stable quality, high efficient reply, very professional and experienced sales service.